Carbon Capture and Storage

Carbon di oxide (CO2) is a green house gas and is estimated to account for more than 60% of the gases responsible for causing anthropogenic climate change. The major concentrated source of CO2 to atmosphere is the CO2 emitted from power plants particularly those using fossil fuels like coal. The term "Carbon Capture and Storage (CCS)" refers to the act of capturing a pure stream of CO2 from the flue gas of these power plants and sequester it in an environmentally safe way. Thus, it can be seen that the CCS is an important activity from the sustainability aspect. Realizing the importance of CCS, many governments have started taking proactive steps. In US, the CCS has been listed as one of the important areas which would be receiving research grants even from the Recovery Act.

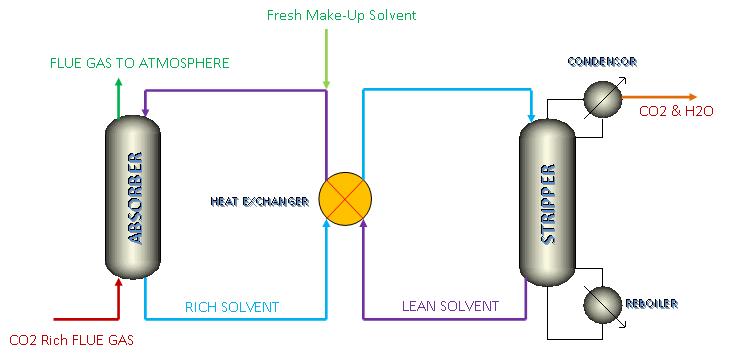

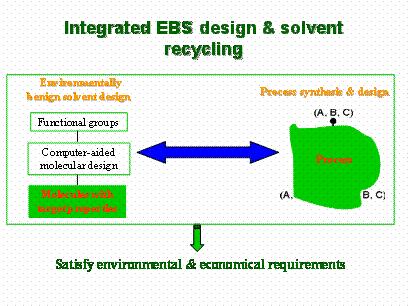

The capture of CO2 can be done by a variety of unit operations like absorption, adsorption, cryogenic distillation and membrane separation. Among all these options, inspite of being a costly and highly energy intensive capture technique, it is the absorption process that has been reported to have the widest commercial viability. This is primarily because this capture technology is the only method ready for large scale application on existing power plants. At VRI, we are focusing on the efficient capture of CO2 using absorption process. The absorption process involves the use of a solvent to absorb the CO2 from the flue gas of the power plant which is subsequently desorbed to obtain a relatively pure stream of CO2. The selection of a solvent needs to done based on two broad criteria viz., better economic performance for the survival of the plant and the selection of benign solvents and greener processes for ensuring sustainability of life on the planet. These objectives can be met by an effective integration of the following steps

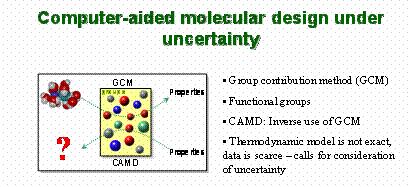

1. Product Design or Chemical Synthesis: This step involves the selection of an effective separating agent (solvent) primarily using computer aided molecular design.

2. Process Synthesis: This step involves the design of the separation process for solvent separation & recycling and relies extensively on simulation models built in ASPEN.

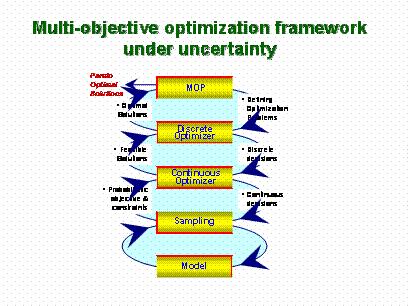

The problem of integrated solvent selection and solvent recycling gives rise to an optimization problem. This optimization is multi-objective problem and can be non-linear in nature involving both discrete and continuous variables. In addition to these inherent mathematical complexities, there are various kinds of uncertainties involved in CCS which can be elegantly handled in such an integrated framework. Some of these uncertainities are the estimation errors, process variations and physical properties of the solvent. Any robust solution to the design of absorption process needs to take into account such uncertainties to address real-life problems. To solve these problems, a five level multi-objective architecture as shown in the figure is to be used.