1. Multi-objective optimization of advanced power systems:

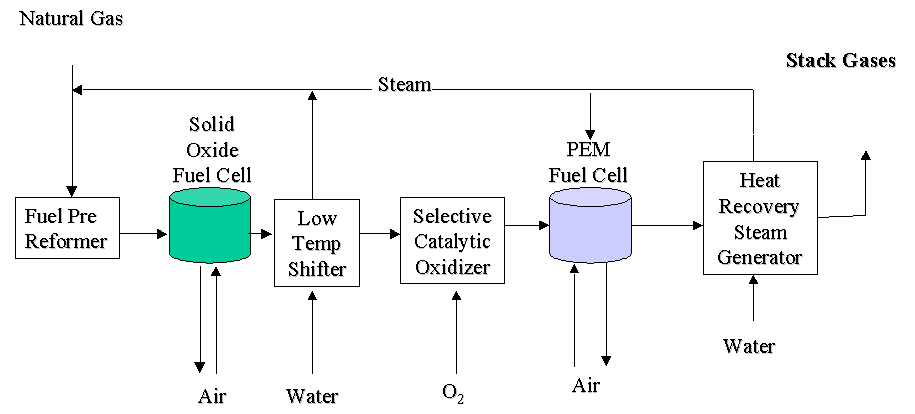

The hybrid power plant design problems often involve multiple and conflicting objectives such as cost, process efficiency and pollutant emissions. The conflicting nature of these objectives makes the handling of this problem an even more formidable task. The solution of a multi-objective problem is a complete non-dominated or Pareto set, which includes the alternatives representing potential compromise solutions among the objectives. This makes a range of choice available to decision makers and provides them with the trade-off information among the multiple objectives effectively. We have worked with three new conceptual designs: 1) the SOFC-PEM hybrid power plant and 2) the SOFC/Steam Turbine (ST) /Gas Turbine (GT) configuration 'FutureGen' power plant, 3) Coal-based H2 coproduction with CO2 capture plant (Advance FutureGen) power plant; and have evaluated and analyzed the trade-offs between the multiple objectives using an efficient multi-objective framework.

The SOFC-PEMFC hybrid power plant

Coal-based H2 coproduction with CO2 capture plant (Advance FutureGen) power plant

2. Uncertainty characterization and quantification:

The hybrid fuel cell technologies are new and futuristic and hence the system level models used for simulating the fuel cellsí performance and other components like the syn-gas desulfurization reaction parameters (in this case the pre-exponential factor and activation energy) have significant uncertainties in them. Also, the performance curves of the SOFC would differ depending on the materials for the anode, cathode and electrolyte and analogously, the performance of a desulfurizer would vary depending on the substance used as the sorbent. A large number of materials need to be considered in the fuel cells for electrolyte issues, electrode performance issues, and for different configurations in order to obtain the desired properties. Hence the development in the area of new materials and other technologies where the performance and economic data is scarce and/or incomplete, calls for consideration of uncertainties in the design and optimization. The crucial steps in uncertainty analysis are characterization and quantification of uncertainty on which the validity of the analysis rests on. Characterization refers to expressing uncertainty in mathematical terms and quantification refers to the representation of uncertainty with probability distribution functions (PDF) illustrating the frequency of occurrence of each uncertainty.

In the case of the SOFC/ST/GT power plant, a two level uncertainty analysis was performed for the fuel cell modules. Performance data i.e. current density (I) vs. voltage (V) data for SOFC were collected and two types of uncertainties were identified

- Material induced uncertainty: Uncertainty due to the various materials used for anode, cathode and electrolyte in the SOFCs resulting in different performance curves. Uncertainty Factor (UF) (defined as the ratio of the experimental voltage to the model calculated voltage at each current density) distributions were computed for 45 different anode-electrolyte-cathode material combinations. The mean and variance for each distribution were estimated and finally, the series of means and variances were fit into two final distributions which represented the total uncertainty induced by materials.

- Model uncertainty: Uncertainty in the parameters used in the SOFC. The UF distribution for a particular material represents the uncertainty associated with purely the model parameters without the 'noise' of material uncertainty.

3. Stochastic simulation capability in Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model:

GREET is a complex model for estimating the full fuel-cycle energy and emission impacts of various transportation fuels and vehicle technologies considering the fuel cycle from wells to wheels and the vehicle cycle through material recovery and vehicle disposal developed by Argonne National Labs. The GREET model incorporates large number of input parameters associated with the output results. Many of the input parameters assumptions involve uncertainties, which require probability distributions to represent the trend of occurrence of the parameter over a specific range defining the uncertainty. Since some of the parametric assumptions in GREET are uncertain, the resulting output variables have to be represented by distributions. To address these uncertainties, we have developed a stochastic simulation tool to incorporate various sampling techniques. The tool has been built through an excel add-in file, developed using Visual Basic macros, which interfaces with the user and calls external files in the form of FORTRAN compiled dynamic link libraries (DLL) to assign probability distributions and perform sampling on the input parameters. The tool also has the capability to perform statistical analysis on the output results.

4. Development of CAPE-OPEN compliant stochastic simulation and multi-objective optimization capability:

The CAPE-OPEN (CO) standards provide a set of interfaces which allows the seamless integration of Computer Aided Process Engineering (CAPE) modules from various sources (software and equipment vendors, universities, and company generated) into process simulation environments. This enables a process engineer to 'assemble' the necessary computational tools with the minimum effort from a collection of software (in-house, commercial, and/or academic) to achieve a best-in-class solution to various CAPE-related problems.

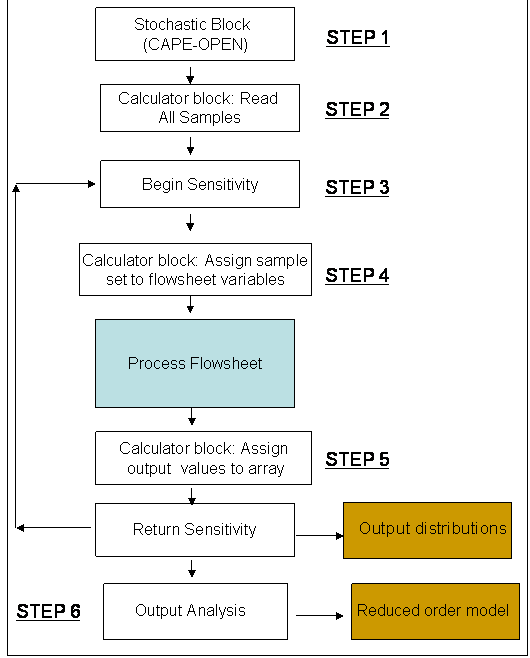

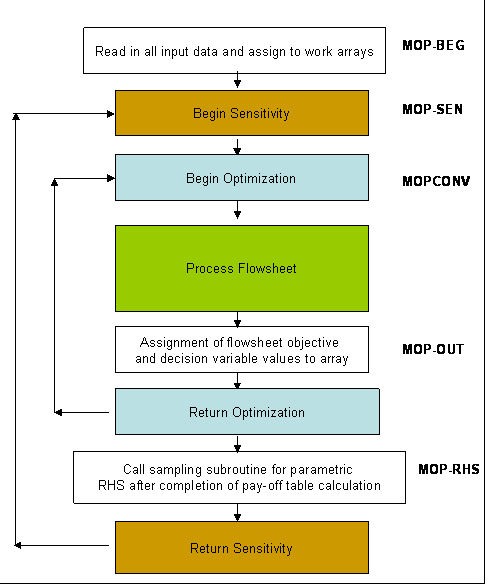

We have created a tool which simplifies the process of setting up a multi-objective optimization framework for any process modeled in the APECS (Advanced Process Engineering Co-Simulator). APECS is an integrated software suite that combines the power of process simulation with high-fidelity, computational fluid dynamics (CFD) for improved design, analysis, and optimization of process engineering systems. The APECS system uses commercial process simulation (e.g., Aspen Plus) and CFD (e.g., FLUENT) software integrated with the process-industry standard CAPE-OPEN (CO) interfaces. This new tool automates the process of setting up a multi-objective optimization framework to a great extent and guides the user in each step of the process through user-friendly graphical user interface (GUI) windows. The tool is CAPE-OPEN compliant and was developed using Visual Basic 6.0 and FORTRAN. The following figure shows the sequence followed by the stochastic simulation automation tool.

We have developed another CAPE-OPEN compliant tool using Visual Basic 6.0 and FORTRAN, to make stochastic simulation and reduced order model calculation more accessible to users The software simplifies the process of setting up a process modeled in the APECS (Advanced Process Engineering Co-Simulator) for stochastic simulation. The following figure shows the sequence followed by the stochastic simulation automation tool.