Optimization of IGCC systems involving chemical looping combustion

Chemical-looping combustion (CLC) is a combustion technology with inherent separation of the greenhouse gas CO2. The technique involves the use of a metal oxide as an oxygen carrier which transfers oxygen from the combustion air to the fuel. Hence the direct contact between fuel and combustion air is avoided. Subsequently, the products from combustion, e.g. carbon dioxide and water, will be kept separated from the rest of the flue gases, e.g. nitrogen and any remaining oxygen. Optimal process synthesis and design of this systems is required in order to make this technology commercially available in the near future.

APECS (Advanced Process Engineering Co-Simulator) is an integrated software suite that combines the power of process simulation with high-fidelity, computational fluid dynamics (CFD) for improved design, analysis, and optimization of process engineering systems. The APECS system uses commercial process simulation (e.g., Aspen Plus) and CFD (e.g., FLUENT) software integrated with the process-industry standard CAPE-OPEN (CO) interfaces. This breakthrough capability allows engineers to better understand and optimize the fluid mechanics that drive overall power plant performance and efficiency. Stochastic modeling and multi-objective optimization capabilities around APECS system and the advanced FLUENT model for gasification processes have been implemented. Uncertainties have been characterized using this rigorous model for the gasifier and used in ASPEN Plus flow sheet. Subsequently, the uncertainties were employed to see the effect on multiple objective optimization.

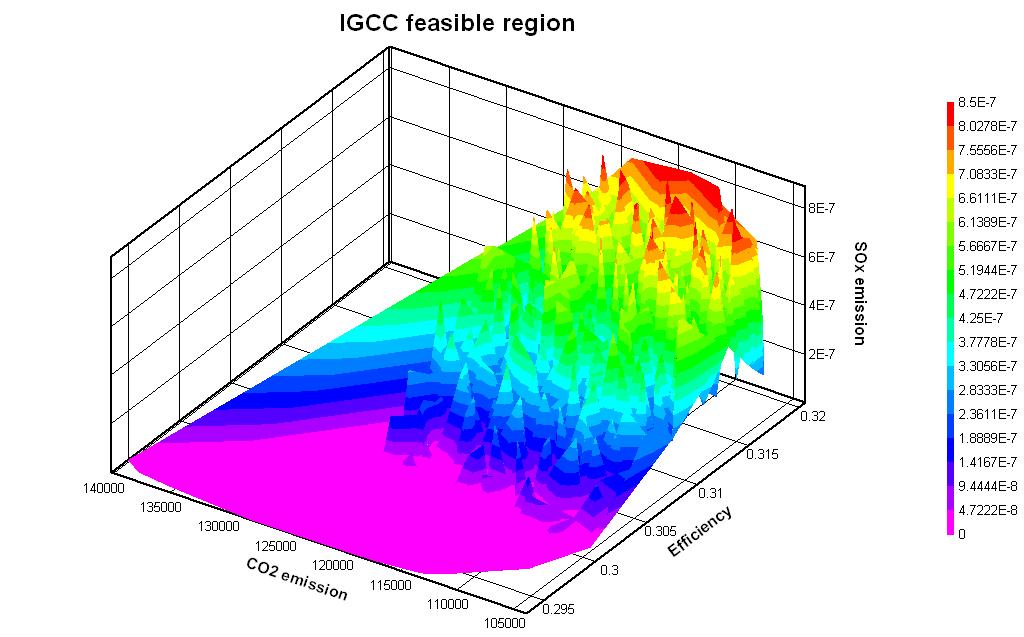

Figure 1 shows the feasible surface for the system and the values of three objective functions: 1). total plant efficiency (based on HHV of coal); 2) total CO2 emissions measures in lb/hr and 3) total SOx emission measured as volumetric fraction of the total flue gas volumetric flow rate. For the simulations in 3-dimensional space. Here, the contours of one of the objectives (SOx) are plotted with respect to the values of the other two objectives for 1000 samples. From the figures it is clearly evident that the trade-off surface is highly non-convex and hence conventional multiobjective optimization techniques cannot be used. The parameter space investigation (PSI) method relying to heuristics based inspection of the feasible region is therefore used to generate the approximate Pareto surface. For multiobjective optimization under uncertainty, the CAPE OPEN compliant block in Aspen Plus is developed. This block is used to find the feasibile space and Pareto surface for optimization under uncertainty. It has been found that the feasibile space and Pareto space shrinks considerably when uncertainty is included and the decision variable space narrows down.

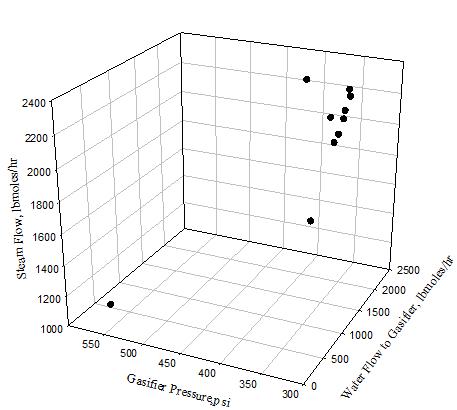

For the gasification system, three decision variables were included: gasifier temperature controlled by water flow, gasifier pressure, and water gas shift reactor (WGS) temperature controlled by the steam flow. Multiobjective optimization was carried out based on these three decision variables with three objectives: cold gas efficiency, net power production, and cost of electricity. Multiobjective optimization capability described above was employed. The approximation of the Pareto surface provided the nondominated region. Therefore, the region of operation can be identified based on this nondominated set as shown in Figure 2. It can be conlcuded that most of the decision variables lie in one small region except two solutions. This can be considered as the optimal operating region for the system.

Figure 1 3-D feasible region and objective function contours for IGCC system

Figure 2 Decision variable region corresponding to nondominated set