Design, analysis and optimization of integrated power plant and water management systems

It is estimated that the power generation will grow 22% by 2030. Water availability for this generation can be as critical as costs. The main goals of this project are:

Estimation of water consumption in power plants is mostly determined be evaporative losses of the cooling tower. This evaporation is strongly associated to the atmospheric conditions of the plant site. Estimation of such evaporative loses is normally done with very little or none information about the weather conditions, therefore very simplistic and conservative calculations are involved. An initial approach to a more realistic model for the estimation of the evaporation in the cooling tower is presented in Figure 1. In this model AIRCT is the air entering the tower through the forced draft fans and WTCIN is the water circulating through the cooling tower. The temperature at which this water enters the condenser is defined by an empirical correlation of the gas/liquid ratio inside the tower and the humidity conditions of the air (dry bulb temperature and relative humidity). The tower model forces the liquid outlet (TWB1) to be zero and evidently HOTAIR to be saturated. In this way, the stream EVA1 represents the evaporative loses.

Other sources of water consumption are considered in the total estimation of water usage. The flue gas desulfurization unit (FGD) requires a makeup stream and the water loses in the cooling tower due to blowdowns and draft are calculated based on the amount of circulating water (WTCIN).

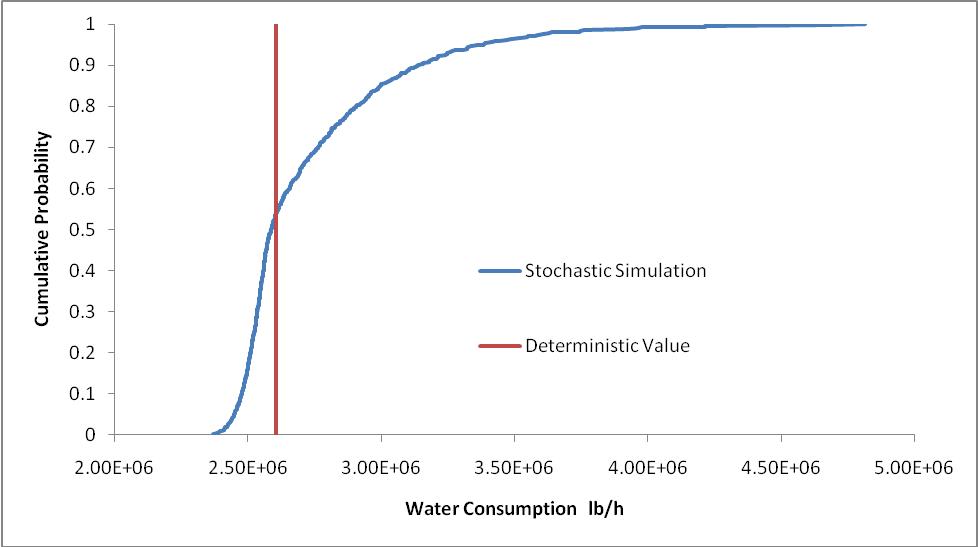

When this model is combined with the comprehensive flowsheet of a power plant and uncertainties associated with weather (impacting cooling air conditions) are included; stochastic simulation is required to determine the distribution of the values that the water consumption may take for each of the potential scenarios. Figure 2 shows how deterministic may be accurate for values that are possible only up to 50% of the time.

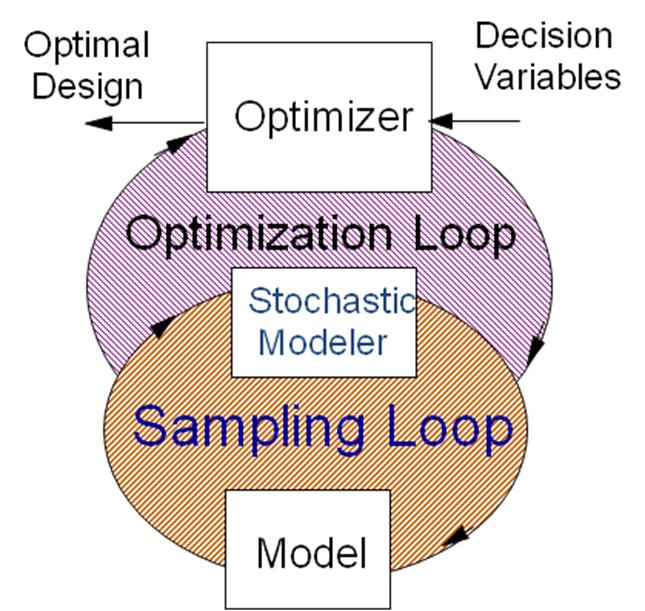

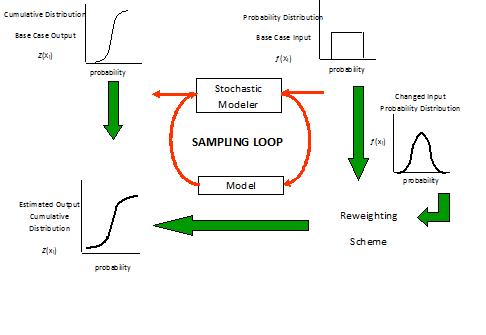

Moments of the distribution resulting from the stochastic simulation become the objective function within the stochastic optimization scheme depicted in Figure 3. Expected value and/or standard deviation of the distributions are fed to the optimizer that determines the decision variables under which all the uncertain variables scenarios have to be evaluated. Naturally, the computational expenses of these schemes are high since for each policy determined by the optimizer all the scenarios of the uncertain variables need to be evaluated to obtain the distribution and its corresponding moments. Optimization under uncertainty is an important tool for water management. Efficient algorithms are required to reduce the calculation efforts; better optimization of non-linear uncertain systems (BONUS) is an excellent example. The algorithm makes use of a re-weighting scheme of the results of a single stochastic simulation involving both uncertain and decision variables to estimate the values of the objective function for different policies generated by a non-linear programming algorithm. The estimation methodology is shown in Figure 4.

Figure 1: Aspen Plus ® model of a cooling tower for a pulverized coal (PC) power plant

Figure 2: Cumulative probability of water consumption in a PC power plant under air temperature and humidity uncertainty

Figure 3: Stochastic optimization scheme

Figure 4: Sampling loop of the BONUS algorithm scheme to estimate the moments of the distribution (objective function of the optimization loop)

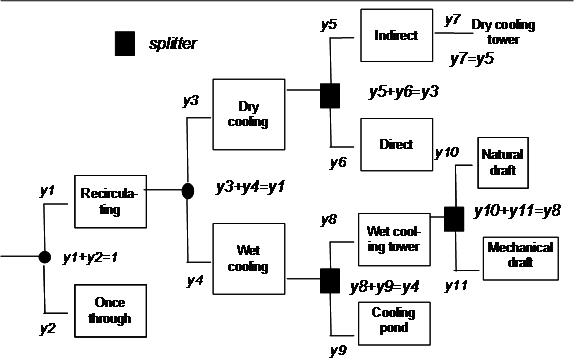

Process conditions can be modified to reduce water consumption, but water reuse and recycle are additional alternatives to reach an inclusive water management strategy. Process integration techniques as heat exchange network synthesis (HENS) and mass exchange network Synthesis (MENS) are employed to incorporate recycle reuse alternatives. These new configuration comprise a range of possibilities from the simplest approaches like direct recycle to more complex applications as novel heat exchange and water treatment technologies. Mathematical programming strategies are employed to optimize the superstructure generated with all these alternatives. A decision tree for the optimization of a superstructure that includes different types of cooling systems is shown in Figure 5.

Figure 5: Decision tree from a superstructure involving different types of cooling systems employed in a power plant